The Recessed Plate Filter Press will compact sludges to a dry cake with a density that is dependent upon the ultimate compaction pressure and the characteristics of the particular sludge.

Each pressload will require from 2-4 hours cycle time. To insure adequate time, the press should be sized for at least 8 hours working capacity.The table and formula below can be utilized to size your press.

To confirm your sizing and evaluate the process for your application with a laboratory-sized model, contact the Application Engineering Dept. to arrange a pilot test.

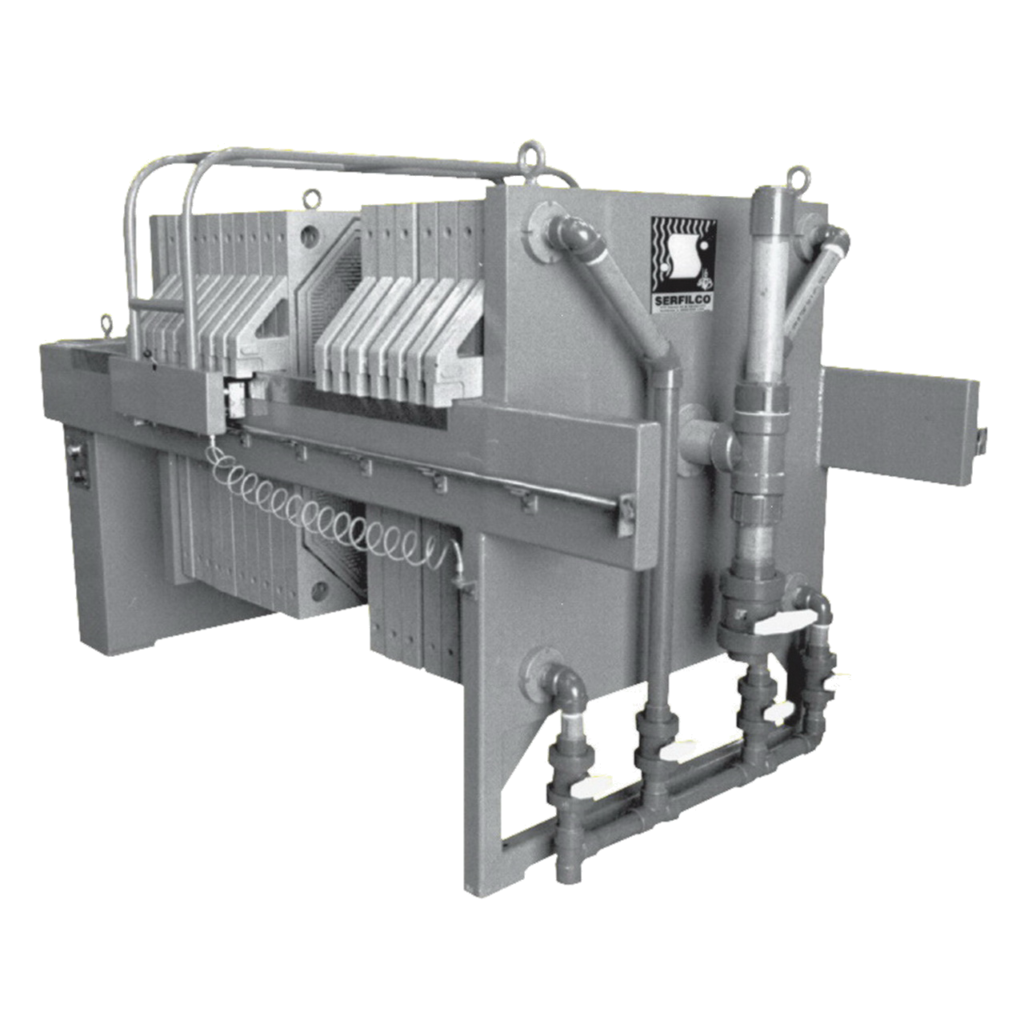

Presses feature structural Steel (ST) frame, coated with tough chemical resistant epoxy paint. High density molded PP filter plates are light weight and corrosion resistant. Special PP quick cake release filter cloths. Air actuated hydraulic system for parting and closing the filter plates. Automatic self-compensating hydraulic system. Conveniently located operator control console.

Application:

LIQUID / SOLID SEPARATION FOR:

WASTE & SEWAGE TREATMENT

BREWING / CEMENT / CERAMIC

MINING & PLATING INDUSTRIES

FOOD & VARNISH PROCESSING CHEMICALS

Performance: .6-50 cu. ft

Features:

- MANUAL HYDRAULIC 0.6 to 3 cu.ft.expandable

- SEMI-AUTOMATIC 1 to 50 cu.ft. expandable

- AIR BLOWDOWN MANIFOLD

- CORROSION RESISTANT

- 40-60% SOLIDS CONCENTRATION

- LOW ENERGY REQUIREMENT

- EASY DROPOUT CLEANING

Product Bulletin

Sales Bulletin

Operation and Service Guide